Page 332 - Full GAP Catalogue 2022

P. 332

330 / Diamond Blades & Consumables Diamond Blades & Consumables / 335

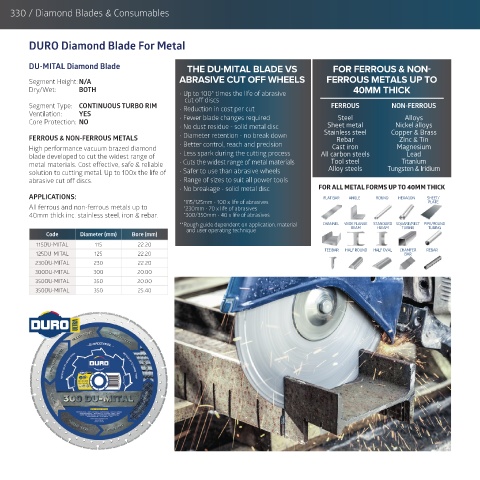

DURO Diamond Blade For Metal

DU-MITAL Diamond Blade THE DU-MITAL BLADE VS FOR FERROUS & NON-

Segment Height: N/A ABRASIVE CUT OFF WHEELS FERROUS METALS UP TO

Dry/Wet: BOTH • Up to 100* times the life of abrasive 40MM THICK

cut off discs

Segment Type: CONTINUOUS TURBO RIM • Reduction in cost per cut FERROUS NON-FERROUS

Ventilation: YES • Fewer blade changes required Steel Alloys

Core Protection: NO

• No dust residue - solid metal disc Sheet metal Nickel alloys

FERROUS & NON-FERROUS METALS • Diameter retention - no break down Stainless steel Copper & Brass

Rebar

Zinc & Tin

High performance vacuum brazed diamond • Better control, reach and precision Cast iron Magnesium

blade developed to cut the widest range of • Less spark during the cutting process All carbon steels Lead

Titanium

Tool steel

metal materials. Cost effective, safe & reliable • Cuts the widest range of metal materials Alloy steels Tungsten & Iridium

solution to cutting metal. Up to 100x the life of • Safer to use than abrasive wheels

abrasive cut off discs. • Range of sizes to suit all power tools

• No breakage - solid metal disc FOR ALL METAL FORMS UP TO 40MM THICK

APPLICATIONS: FLAT BAR ANGLE ROUND HEXAGON SHEET/

All ferrous and non-ferrous metals up to *115/125mm - 100 x life of abrasives PLATE

*230mm - 70 x life of abrasives

40mm thick inc. stainless steel, iron & rebar. *300/350mm - 40 x life of abrasives

**Rough guide dependent on application, material CHANNEL WIDE FLANGE STANDARD SQUARE/RECT PIPE/ROUND

BEAM

TUBING

I-BEAM

TUBING

Code Diameter (mm) Bore (mm) and user operating technique

115DU-MITAL 115 22.20

125DU-MITAL 125 22.20 TEE BAR HALF ROUND HALF OVAL CHAMFER REBAR

BAR

230DU-MITAL 230 22.20

300DU-MITAL 300 20.00

350DU-MITAL 350 20.00

350DU-MITAL 350 25.40